Small Engine checking and repair

To check and repair a Small Engine, you should start with safety and move through each step with care. Most problems can be solved with patience and simple tools. Many issues happen because of fuel problems, dirty carburetors, air filter blockages, rope damage, or spark plug trouble.

Tip: You can fix most engine issues at home if you follow clear instructions and stay calm.

Key Takeaways

-

Prioritize safety by setting up a clean, well-lit workspace and wearing protective gear. This helps prevent accidents and injuries.

-

Diagnose engine issues step by step, starting with simple checks like fuel quality and spark plug condition. Many problems stem from basic issues.

-

Regular maintenance is key. Change oil, clean air filters, and inspect spark plugs to keep your engine running smoothly and extend its life.

-

Use fresh gasoline and clean the carburetor regularly to avoid common fuel system problems. This prevents starting issues and engine stalls.

-

Proper storage of your engine during inactivity is crucial. Use fuel stabilizers and keep it in a dry place to ensure easy starts next season.

Safety First

Before you start any small engine repair, you need to make safety your top priority. Taking the right precautions protects you from injury and keeps your workspace organized.

Workspace Setup

Set up your workspace in a clean, well-lit area. Remove any clutter or debris that could cause you to trip or slip. Always work in a space with good ventilation. Gasoline engines produce carbon monoxide, which can be dangerous in closed spaces. Keep a fire extinguisher nearby and make sure you have easy access to exits.

Tip: A clear work area helps you avoid accidents and makes it easier to find your tools.

Here are some key safety guidelines you should follow:

|

Safety Guidelines |

Description |

|---|---|

|

Check oil level |

Make sure the oil level is correct before starting the engine. |

|

Use recommended oil |

Use the oil type listed in your manual. |

|

Proper fuel mixture |

Mix oil and gasoline as directed if your engine requires it. |

|

Cool down before refuel |

Let the engine cool before adding fuel. |

|

Store gasoline safely |

Use approved containers for gasoline. |

|

Ventilation |

Work in a well-ventilated area. |

|

Clear work area |

Remove debris and obstacles. |

Protective Gear

Wear the right protective gear every time you work on a small engine. Safety goggles protect your eyes from flying debris. Gloves keep your hands safe from sharp parts and hot surfaces. Closed-toe, non-slip shoes prevent slips and protect your feet from heavy objects.

Engine Off Procedures

Always turn off the engine before you begin any checks or repairs. Disconnect the spark plug wire to prevent accidental starting. Let the engine cool down before you touch any parts, especially the muffler or engine block. Hot surfaces can cause burns. If you need to move the engine, make sure all moving parts have stopped.

Remember: Safety checks before and after use help keep your machine in good condition and prevent injuries.

Small Engine Diagnosis

Diagnosing a Small Engine helps you find the root cause of problems quickly. You need to check each system step by step. This section guides you through the most common checks and symptoms.

Won’t Start Checks

If your Small Engine will not start, follow these steps:

-

Set all switches to the correct position. Make sure the throttle is open and the air valve is closed. Move the turtle and rabbit lever to "turtle." Pre-pull the starter rope 2-5 times, then open the air valve and pull again.

-

Check the oil level. Add or change oil if needed.

-

Inspect the fuel tank. Use fresh gasoline. Stale fuel can prevent starting.

-

Look at the carburetor. Clean it if you see dirt or buildup.

-

Examine the spark plug. Replace it if it looks worn or damaged.

-

Test the ignition system. Make sure you see a spark when you pull the starter.

-

Check the sensor wire. If the sensor prevents starting, disconnect it. This will not harm the engine.

-

Inspect the fuel tank vent pipe. If you see a blockage, unplug the pipe to allow fuel to flow.

-

Assess the valves and compression. Use a compression tester to check for proper pressure.

Tip: Always start with the simplest checks. Many problems come from old fuel, dirty parts, or loose wires.

Common Symptoms

You may notice different symptoms when your engine has trouble. Each symptom points to a possible cause.

|

Symptoms |

Likely Causes |

|---|---|

|

Failure to start |

Bad gasoline, dirty carburetor, bad spark |

|

Difficulty starting |

Weak spark, fuel delivery problems, low compression, carburetor issues, dirty fuel |

|

Stalling immediately |

Blocked fuel line, malfunctioning choke, severe carburetor problem |

|

Stalling during operation |

Overheating, clogged air filter, serious engine issue |

-

Failure to start: You may have bad gasoline, a dirty carburetor, or a faulty spark plug.

-

Difficulty starting: Weak spark, fuel delivery problems, or low compression can cause this.

-

Stalling immediately: Blocked fuel lines or a malfunctioning choke often lead to this issue.

-

Stalling during operation: Overheating or a clogged air filter may be the reason.

Note: If you see smoke from the exhaust, check for oil or fuel problems. This can help you spot issues early.

System Checks

Fuel System

Start by checking the fuel in your Small Engine. Old or stale gasoline can cause starting problems. Look for signs of ethanol damage, which can harm rubber and plastic parts. You may notice cracks or leaks. Clogged carburetors often cause engines to stall or make starting hard. Open the carburetor and look for sticky deposits or dirt. Microbial growth can also appear in the fuel, especially if you store your engine for long periods. Use a flashlight to inspect the fuel tank for any dark spots or slime.

Common fuel system problems include:

-

Ethanol damage to rubber and plastic parts

-

Clogged carburetors from fuel deposits

-

Microbial growth in the fuel tank

Tip: Always use fresh gasoline and clean the carburetor regularly to prevent these issues.

Ignition System

Next, check the ignition system. A faulty ignition can stop your engine from running smoothly. Watch for misfiring, which feels like coughing or sputtering. You might feel jerking or notice strong vibrations when the engine idles. Backfiring creates loud noises and a strong gasoline smell. Sometimes, you will see darker exhaust smoke. Reduced gas mileage can also point to ignition problems. Oil leaks around ignition coils may cause misfires.

Signs of ignition system failure:

-

Misfiring or sputtering

-

Backfiring with loud noise and dark exhaust

-

Reduced gas mileage

-

Oil leaks near ignition coils

Combustion Parts

Inspect the spark plug and air filter. A fouled spark plug can prevent the engine from starting. Remove the spark plug and check for black soot or oil. Replace it if needed. A dirty air filter blocks airflow and reduces power. Hold the filter up to the light. If you cannot see through it, replace it. Check the valves for proper movement. Use a compression tester to make sure the engine has enough pressure for combustion.

Cooling & Lubrication

Check the cooling fins and oil level. Clean any dirt or grass from the cooling fins to prevent overheating. Make sure the oil is at the correct level and looks clean. Excessive crankcase pressure can cause oil leaks and lower performance. Signs include oil in the air cleaner base, smoke from the oil gauge, or oil forced into the ventilation system. Make sure the ventilation system works well to avoid pressure buildup.

Note: Regularly check for oil leaks and keep the ventilation system clear to maintain engine health.

Cleaning & Repairs

Carburetor Cleaning

A clean carburetor helps your engine run smoothly. Gum and varnish from old fuel often cause carburetor problems. You can fix this by cleaning the carburetor with the right method. Follow these steps:

-

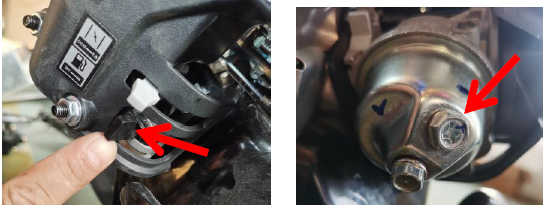

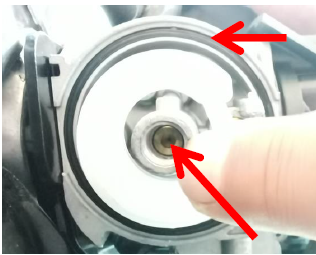

Turn off the oil circuit switch and turn it to the "OFF" side; loosen the bolt pointed by the red arrow in the right figure and drain the gasoline in the oil cup.

-

Loosen the bolt pointed by the red arrow in the right picture and remove the oil cup.

-

Clean the oil cup and remove impurities.

-

Use an air gun or a thin metal needle to unclog the oil hole at the location indicated by the red arrow.

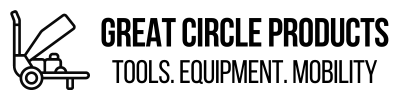

After cleaning, you can restore it. Make sure the black sealing ring is in the groove as indicated by the arrow in the figure above

Spark Plug Replacement

A fresh spark plug keeps your engine firing strong. Replace it by following these steps:

-

Gather your tools: spark plug wrench, socket, and gap gauge.

-

Disconnect the spark plug wire. Remove the old spark plug with the wrench.

-

Use the gap gauge to check the new spark plug’s gap. Adjust if needed.

-

Hand-tighten the new spark plug. Use the wrench to secure it, but do not overtighten.

-

Reconnect the spark plug wire. Make sure it fits snugly.

Check spark plugs often. Clean dirty plugs with a wire brush and carburetor cleaner. Replace them as your manual suggests.

Part Replacement

Sometimes, you need to replace worn or damaged parts. Look for cracks, rust, or broken pieces on belts, filters, and hoses. Always use parts that match your engine’s model. Keep a record of what you replace and when. This helps you track maintenance and spot patterns in wear.

Tip: Regular cleaning and timely part replacement keep your engine running longer and prevent bigger problems.

Maintenance Tips

Regular maintenance keeps your engine running longer and prevents breakdowns. Here are some key tips:

-

Change the oil after the first 5 hours of use on a new engine. Then, change it every 25 to 50 hours or at least once a year.

-

Clean or replace the air filter often to keep airflow strong.

-

Check and replace spark plugs every 50 hours or if you see wear.

-

Use clean fuel and inspect the fuel system for clogs.

-

Tighten bolts and fasteners to prevent loose parts.

-

Keep the cooling system clean to avoid overheating.

|

Task |

Frequency |

|---|---|

|

Oil Change |

Every 25–50 hours |

|

Air Filter Clean/Replace |

Regularly |

|

Spark Plug Check/Replace |

Every 50 hours |

|

Fuel System Inspection |

Regularly |

Good habits now save you time and money later.

Storage

Proper storage protects your engine during long periods of inactivity. If you plan to store your engine for more than 30 days, follow these steps:

-

Store the engine in a dry, temperature-controlled place.

-

Add a fuel stabilizer and run the engine for a few minutes, or drain the fuel system completely.

-

Clean the engine and check for any issues before storing.

-

Lubricate all moving parts as your manual suggests.

-

Keep the engine covered and away from moisture.

A little care before storage helps your engine start easily next season.

You can keep your small engine running smoothly by following these steps:

-

Start with safety.

-

Diagnose issues early.

-

Check fuel, ignition, and cooling systems.

-

Clean and replace parts as needed.

-

Maintain your engine regularly.

Regular maintenance prevents breakdowns, saves money, and extends engine life. You help the environment by repairing instead of replacing. Begin your own maintenance routine today and enjoy reliable performance every season.

FAQ

How often should you change the oil in a small engine?

You should change the oil after the first 5 hours of use. After that, change it every 25 to 50 hours or at least once a year. Clean oil keeps your engine running smoothly.

What should you do if your engine still won’t start after basic checks?

Double-check the fuel, spark plug, and air filter. Try using fresh gasoline. If the engine still does not start, inspect the carburetor for dirt. You may need to clean or replace it.

How can you prevent fuel problems in your small engine?

Always use fresh gasoline. Add a fuel stabilizer if you plan to store the engine for more than 30 days. Drain the fuel tank before long-term storage to avoid clogs and stale fuel.

Why does your engine stall after running for a few minutes?

A blocked fuel tank vent pipe can cause stalling. Unplug the vent pipe to restore fuel flow. Also, check for dirty carburetors or clogged air filters. Clean these parts to keep the engine running.

Dejar un comentario